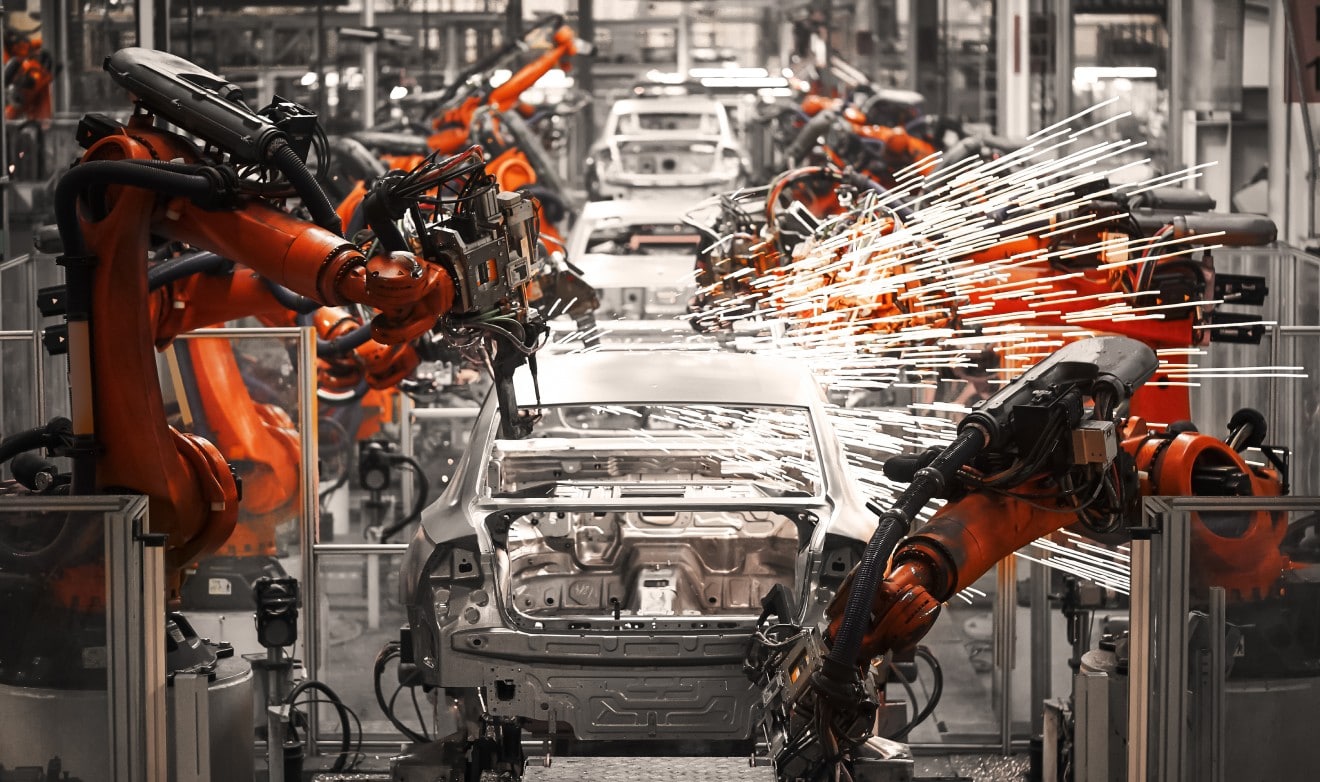

Accelerating Automotive Design: The Role of Rapid Prototyping

The automotive industry has witnessed a remarkable transformation over the years, driven by advancements in technology and a growing emphasis on innovation. One of the key drivers of this transformation is rapid prototyping, a crucial process that has revolutionized automotive design and development. In this article, we will delve into the significance of rapid prototyping in automotive design, exploring its benefits, applications, and its role in accelerating the creation of cutting-edge vehicles.

The Foundation of Rapid Prototyping

Rapid prototyping, often referred to as 3D printing, is a process that allows for the quick and cost-effective creation of physical prototypes directly from digital 3D CAD models. This technology has found widespread use across industries, but its impact on the automotive sector is particularly profound. Here’s why:

1. Speeding Up the Design Cycle

One of the most significant advantages of auto parts manufacturing in automotive design is the ability to dramatically reduce the time required to develop and iterate on new vehicle designs. Traditional methods of creating physical prototypes, such as clay modeling or CNC machining, are time-consuming and costly. Rapid prototyping, on the other hand, allows designers to produce physical models within hours or days, enabling rapid design iterations.

2. Cost Efficiency

While initial investments in rapid prototyping equipment and materials may seem substantial, they are quickly offset by the cost savings achieved in the design and development process. Traditional prototyping methods involve significant labor costs and materials wastage, which can be significantly reduced with 3D printing.

3. Enhanced Creativity and Innovation

Rapid prototyping unleashes the creative potential of automotive designers. It allows them to experiment with unconventional shapes and designs that might have been deemed too complex or expensive to explore using traditional methods. As a result, we see more innovative and aesthetically appealing vehicles on the road.

Applications of Rapid Prototyping in Automotive Design

Rapid prototyping has a wide range of applications in the automotive industry, transforming various aspects of vehicle design and development:

1. Concept Car Development

Concept cars are the epitome of automotive innovation and design. Rapid prototyping plays a pivotal role in creating concept cars that push the boundaries of what’s possible. Designers can quickly translate their vision into tangible prototypes, allowing for rapid feedback and refinement.

2. Functional Prototyping

Beyond aesthetics, rapid prototyping is used to create functional prototypes of vehicle components. This includes parts like engine components, interior features, and even entire vehicle chassis. These prototypes enable engineers to test and refine the functionality of critical systems.

3. Customization and Personalization

In an era where personalization is increasingly important to consumers, rapid prototyping enables automakers to offer customizable options for their vehicles. Customers can choose from a variety of personalized features, such as interior design elements or custom bodywork, with these designs brought to life quickly through 3D printing.

4. Tooling and Manufacturing Aids

Rapid prototyping is not limited to the design phase; it extends into the manufacturing process as well. Automakers use 3D printing to create specialized tools, jigs, and fixtures that aid in the production of vehicles. This streamlines manufacturing processes and enhances precision.

5. Sustainability Initiatives

The automotive industry is making strides towards sustainability. Rapid prototyping supports these efforts by reducing material wastage. 3D printing only uses the exact amount of material needed, reducing environmental impact.

Challenges and Advances

While rapid prototyping has revolutionized automotive design, it is not without its challenges. Material limitations, the need for post-processing, and cost considerations are some of the issues that designers and engineers face. However, ongoing advances in rapid prototyping technologies are addressing these challenges.

1. Advanced Materials

In recent years, there has been a surge in the development of specialized 3D printing materials tailored to the automotive industry. These materials offer enhanced strength, durability, and heat resistance, making them suitable for a wider range of applications.

2. Post-Processing Automation

Automated post-processing solutions are emerging to streamline the finishing of 3D printed parts. This reduces the manual labor required and ensures a more consistent quality finish.

3. Large-Scale Printing

Advancements in large-scale 3D printing have enabled the creation of full-sized vehicle prototypes and components. This opens up new possibilities for creating larger and more complex automotive designs.

Conclusion

Rapid prototyping has emerged as a game-changer in the automotive industry, revolutionizing the way vehicles are designed, developed, and manufactured. Its ability to accelerate the design cycle, enhance creativity, and drive innovation has led to the creation of vehicles that are not only visually stunning but also technologically advanced and functional.

As the technology continues to evolve, we can expect even more significant contributions from rapid prototyping in the automotive sector. From designing the next generation of electric vehicles to crafting personalized car interiors, 3D printing will remain at the forefront of automotive innovation.

In a rapidly changing automotive landscape where consumer preferences are evolving, environmental concerns are paramount, and technological advancements are relentless, rapid prototyping stands as a critical tool that enables automakers to adapt and thrive. It is not merely a part of the automotive design process; it is an engine of progress that propels the industry into an exciting and sustainable future.