How To Make a Perforated Tube With A Tube Laser Cutting Machine?

Introduction to Perforated Tubes

Perforated tubes are vital in diverse industries’ capability in several applications. These tubes have tiny holes for air, fluids, or mild to pass through. They remain strong despite these perforations. It’s like giving them secret pathways to let things flow while keeping them sturdy and robust. They have unique features that make them versatile in various applications. They can do different jobs because they have exceptional qualities.

Have you ever wondered how perforated tubes are made and what makes them so versatile? What are the essential concerns in designing and generating those tubes? Perforated tubes are only one of the most effective or sensible choices for many applications. But, their aesthetic appeal makes them a significant concern in many industries.

Let’s dive into the world of perforated tubes! We’ll learn everything about them, from what they are to how they’re used in different industries. We’ll also discuss the materials used to make perforated tubes and how they’re laid out. We’ll also explore the various ways they’re made, like tube laser cutting.

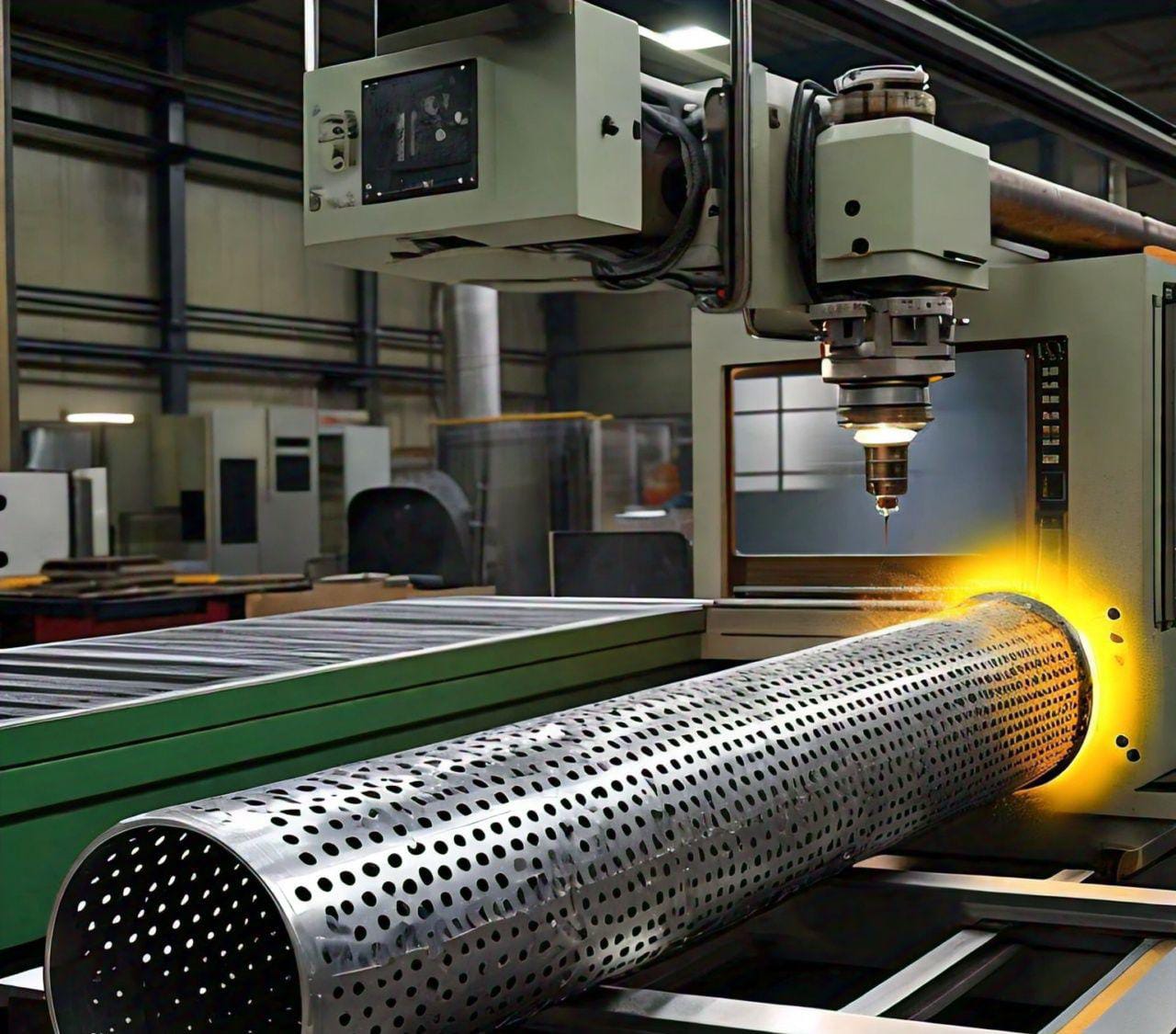

Understanding Tube Laser Cutting Machines

Imagine a magic wand that cuts through metal tubes like butter. That’s what a tube laser-cutting machine is! It’s like having a superhero in the workshop, making precise cuts with a light beam. When you understand how these machines work, you unlock a secret power. This power enables you to create amazing things. With tube laser-cutting machines, dreams take shape, and metal bends to our will.

Designing Perforated Tubes for Laser Cutting

Imagine being an artist with a laser as your paintbrush. You could create beautiful designs on tubes with remarkable precision and detail. Designing perforated tubes for laser cutting is like sculpting dreams into reality. Each cut is like carving out a piece of your imagination, turning ordinary tubes into works of art. It’s a magical journey where creativity meets technology.

This fusion fills our hearts with wonder and excitement! Learn More) They also ensure compatibility with materials and manufacturing methods. Designers create perforated tubes for diverse applications by combining creativity with technical expertise.

Setting Up the Tube Laser Cutting Machine

Setting up the tube laser cutting machine is like preparing for a grand adventure! It’s like building a spaceship, ensuring everything is correct before liftoff. With each button pressed and lever pulled, it’s as if we’re setting the stage for a spectacular show. As the machine hums to life, our hearts race with anticipation. We’re one step closer to turning dreams into reality with every cut!

Laser Cutting Process for Perforated Tubes

Let’s embark on a journey where lasers work like tiny superheroes, cutting holes in tubes! The laser-cutting process for perforated tubes is akin to a magical spell. It can transform solid metal into intricate patterns with mesmerizing precision. As the laser dances across the surface, it’s like watching a dazzling light show. With each precise cut, we witness the power of technology shaping our world. It does so with beauty and precision, leaving us in awe of its capabilities.

Creating Perforated Patterns

Think of creating perforated patterns like painting pictures with holes! It’s like sprinkling stardust on plain surfaces, turning them into mesmerizing artworks. With every punch, you add a touch of magic. This transforms ordinary materials into something extraordinary. It’s a joyful process that sparks creativity. It fills the world with endless possibilities!

Advantages of Perforated Tube Production

Perforated tube manufacturing provides numerous benefits in diverse industries. Let’s dive into the treasure chest of advantages of perforated tube production! It’s like discovering a magical world where every hole holds a secret blessing. With perforated tube production, we unlock the door to creativity. It’s a journey of excitement and wonder where innovation meets opportunity. This paints smiles on faces and dreams in our hearts!

Efficiency in Manufacturing

Efficiency in manufacturing is like a superhero swooping in to save the day! It’s all about making things faster, better, and less effortless. When machines and workers work together smoothly, it creates a symphony of productivity. This fills our hearts with pride, knowing that teamwork yields excellent results. Efficiency brings smiles and ensures that dreams become reality in the blink of an eye!

Cost-effectiveness and Sustainability

Cost-effectiveness and sustainability are like superheroes teaming up to save the day! When we opt for cost-effective solutions, we make intelligent decisions that save money. This brings smiles as we see the positive impact on our finances and happiness. And when we add sustainability to the mix, we hug the planet, making sure our choices are kind to the Earth.

It’s like peeking into the future, where every hole tells a story of progress and possibility. It’s an exhilarating experience to be part of this dynamic industry. Let’s embrace these trends with open arms and hearts full of curiosity. We’re ready to witness the next chapter in the art of perforated tube creation!

Conclusion

It helps them create things better and faster, making the world more amazing! They help find flexible solutions, making things easier for everyone. Understanding the laser slicing era and designing perforated styles guarantees green fabrication. Suitable substances and device setup ensure regular tube manufacturing. Perforated tubes bring blessings like performance and sustainability.

They shine brightly in cutting-edge industries, showing how important they are. Perforated tubes will remain important as Destiny focuses on era and sustainability. They’ll use innovation to meet the needs of businesses.