The Role of Backdrill PCB Technology in Modern Electronics

Introduction

Backdrilling is a technique used in PCB (Printed Circuit Board) manufacturing to remove unused portions of vias to improve signal integrity in high-speed electronic devices.

In this article, we will explore the role of backdrill PCB technology in modern electronics and its impact on signal integrity and overall performance.

Understanding Backdrill PCB Technology

What is Backdrilling?

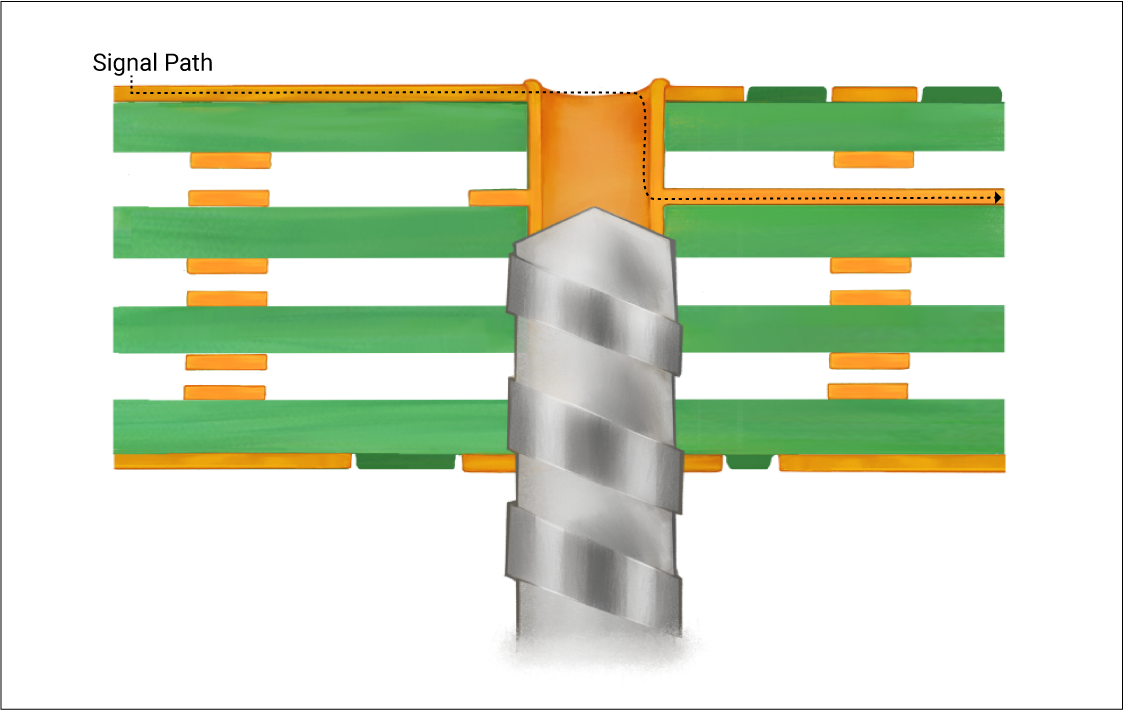

Backdrilling, also known as controlled depth drilling, is a process used to remove the stub portion of vias that are not connected to an outer layer of the PCB. This helps eliminate signal reflections and impedance mismatches that can occur in high-speed circuits. KingSun PCB‘s Backdrill technology is already quite mature in the PCB circuit board market.

How Does Backdrilling Work?

The backdrilling process involves drilling out the unused portion of the via from the back side of the PCB, leaving only the portion of the via that is connected to the outer layer. This reduces the overall length of the via and improves signal integrity.

Importance of Backdrill PCB Technology in Modern Electronics

Signal Integrity

One of the primary benefits of backdrill PCB technology is its ability to improve signal integrity in high-speed electronic devices. By removing the unused portions of vias, backdrilling helps reduce signal reflections and impedance mismatches, leading to more reliable signal transmission.

High-Speed Design Requirements

In modern electronics, the demand for high-speed data transmission has increased significantly. Backdrill PCB technology plays a crucial role in meeting these requirements by ensuring that signals are transmitted accurately and efficiently, even at high speeds.

Reduced Signal Distortion

Signal distortion can occur due to various factors, including impedance mismatches and signal reflections. By using backdrill PCB technology, designers can reduce signal distortion and improve the overall performance of their electronic devices.

Enhanced Signal Integrity in Multilayer PCBs

Multilayer PCBs are commonly used in modern electronics to accommodate complex circuit designs. However, signal integrity can be a challenge in these PCBs due to the increased number of vias. Backdrill PCB technology helps address this challenge by improving signal integrity in multilayer PCBs.

Implementing Backdrill PCB Technology

Design Considerations

Designing a PCB with backdrilling in mind requires careful consideration of several key factors to ensure the effectiveness of the technology. Here are some important design considerations for implementing backdrill PCB technology:

Via Placement:

- Place vias strategically to minimize signal reflections and impedance mismatches.

- Avoid placing vias too close to high-speed signal traces to prevent signal interference.

Via Size and Type:

- Use appropriate via sizes and types for the intended application.

- Consider using blind or buried vias to reduce signal distortion and improve signal integrity.

Signal Integrity Analysis:

- Perform signal integrity analysis to identify potential signal integrity issues.

- Use simulation tools to optimize via placement and routing for improved signal integrity.

Drill Depth and Diameter:

- Determine the appropriate drill depth and diameter for backdrilling based on the PCB thickness and design requirements.

- Ensure that the backdrilled holes do not compromise the structural integrity of the PCB.

Layer Stackup:

- Optimize the layer stackup to minimize the number of vias and reduce signal distortion.

- Consider using symmetrical layer stackups to improve signal integrity.

Thermal Considerations:

- Ensure that backdrilling does not impact the thermal performance of the PCB.

- Consider using thermal vias or additional heat dissipation methods if needed.

Manufacturability:

- Design the PCB for ease of manufacturing, taking into account the capabilities of the PCB manufacturer.

- Provide clear documentation and instructions for the backdrilling process to avoid errors during manufacturing.

Manufacturing Process

The backdrilling process is typically carried out after the PCB has been manufactured. Specialized equipment is used to drill out the unused portions of vias from the back side of the PCB. Care must be taken during this process to avoid damaging the PCB.

Conclusion

Backdrill PCB technology plays a critical role in modern electronics by improving signal integrity and reducing signal distortion in high-speed electronic devices.

As the demand for high-speed data transmission continues to grow, backdrill PCB technology will remain an essential tool for ensuring the reliable operation of electronic devices. If you want to see more of the latest PCB technology, please visit KingSun PCB official website: https://kingsunpcba.com/